The Micro-Physics of Durability: Decoding MEMS Microphones and IPX6 Engineering in the iLuv TB200

Update on Nov. 22, 2025, 6:06 p.m.

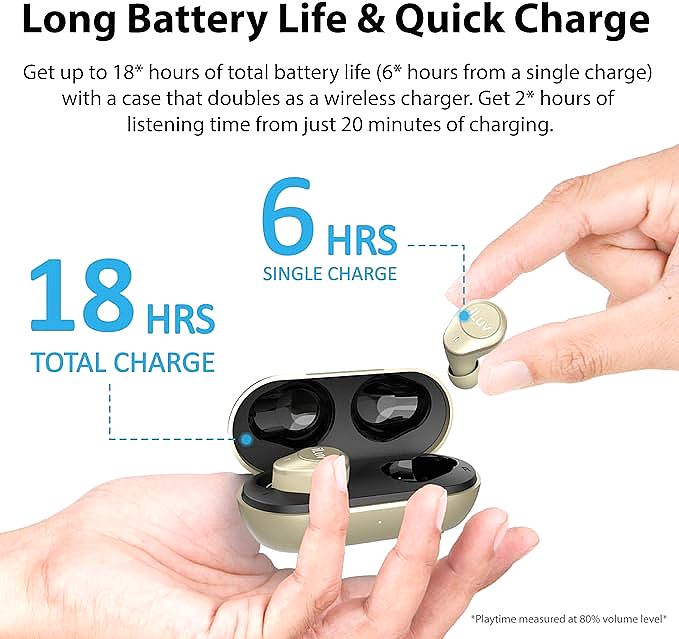

In the grand scheme of personal technology, the True Wireless Stereo (TWS) earbud is an anomaly. It packs a radio transceiver, a battery, an audio driver, a microphone, and a computer processor into a chassis smaller than a grape. The iLuv TB200 exemplifies this miniaturization trend, offering a robust feature set at an accessible entry point.

To appreciate devices like the TB200, we must zoom in—past the plastic shell—to the microscopic engineering that makes them possible. This is a story of silicon mechanics, hydrodynamic seals, and the physics of human electricity.

Silicon Ears: The Physics of MEMS Microphones

The TB200 claims “Clear Crisp Hands-Free Call” capability. This is powered by MEMS (Micro-Electro-Mechanical Systems) technology. Unlike traditional electret microphones that use a bulky fabric diaphragm, MEMS microphones are etched directly onto a silicon chip.

- The Mechanism: A MEMS microphone consists of a pressure-sensitive diaphragm etched into silicon, suspended over a backplate. Sound waves cause the diaphragm to move, changing the capacitance between it and the backplate. An ASIC (Application-Specific Integrated Circuit) converts this capacitance change into an electrical signal.

- The Advantage: This solid-state construction makes the microphone incredibly consistent and resistant to mechanical shock and temperature variations. It allows for “Wideband Speech” capture in a package often smaller than a grain of rice, enabling clear voice transmission without consuming significant internal volume.

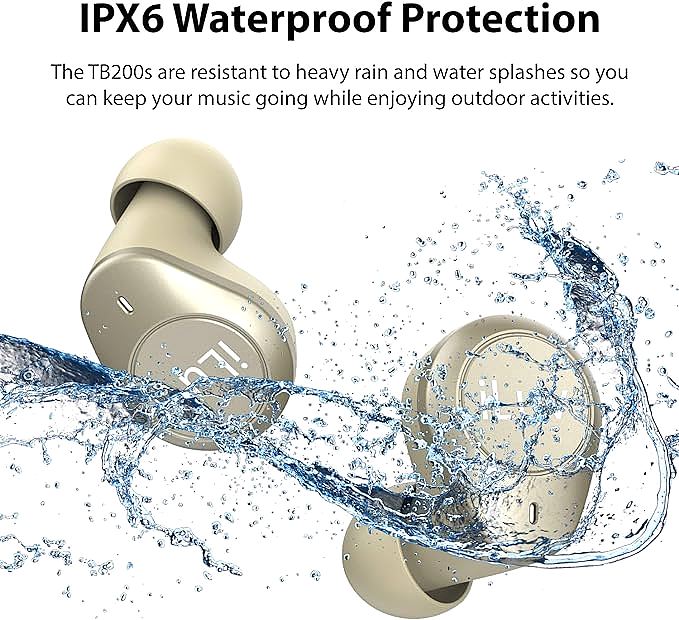

Hydrodynamics: Decoding the IPX6 Rating

Water resistance is often misunderstood. The TB200 carries an IPX6 rating. In the IEC 60529 standard, this is distinct from the more common IPX4 (splash) or IPX7 (immersion).

- The Test: IPX6 denotes protection against “Powerful Water Jets.” The device is blasted with 100 liters of water per minute from a 12.5mm nozzle at a pressure of 100 kPa.

- The Engineering: To pass this, the earbud cannot rely on simple tight tolerances. It requires Hydrophobic Acoustic Mesh covering the driver and microphone ports. This mesh uses surface tension principles to prevent water molecules from passing through while allowing air (sound) to flow freely. Internally, rubber gaskets and conformal coatings on the PCB (Printed Circuit Board) provide secondary lines of defense against high-velocity water intrusion.

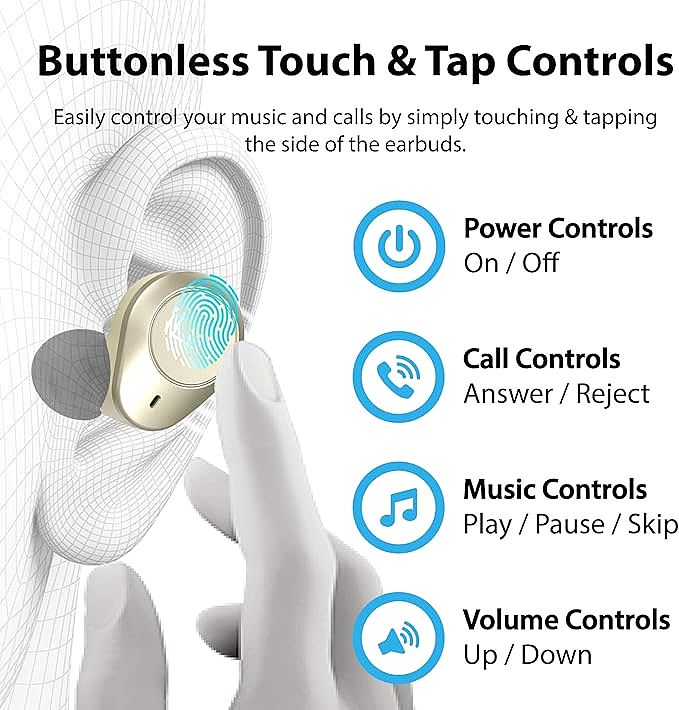

The Human Circuit: Capacitive Touch Controls

Physical buttons are failure points; they require holes in the casing. The TB200 utilizes “Buttonless Touch Controls,” which relies on Capacitive Sensing.

- The Body as a Capacitor: The human body is electrically conductive. The earbud’s outer shell conceals an electrode. When your finger approaches, it acts as a second plate of a capacitor, altering the local electrostatic field.

- Durability: Because there are no moving parts to wear out and no gaps for water to enter, capacitive controls significantly enhance the device’s longevity. The “button” is effectively part of the solid plastic housing, immune to mechanical fatigue.

Connectivity: The Bluetooth 5.0 Handshake

The invisible tether of the TB200 is Bluetooth 5.0. This protocol update was a watershed moment for TWS devices. * Data Throughput: Version 5.0 doubled the potential data speed to 2 Mbps compared to 4.2. This wider “pipe” allows for faster handshakes (pairing) and more robust error correction, reducing the audio dropouts that plagued early wireless earbuds. * Independent Signaling: The TB200 employs “Independent Connection,” meaning each earbud negotiates its own link with the phone. This replaces the older “Master-Slave” topology (where one bud relayed signal to the other), halving latency and balancing battery consumption.

Conclusion: The Standardization of Excellence

The iLuv TB200 is a testament to the power of industrial standardization. Features that were once cutting-edge science—MEMS fabrication, hydrophobic nanocoatings, capacitive sensing—are now robust, affordable commodities. By integrating these technologies, the TB200 offers a level of durability and performance that defies its price point, proving that advanced engineering is no longer the exclusive domain of luxury electronics.