Decoding Earbud Drivers: Why Material (like PEEK+PU) Matters More Than Size

Update on Nov. 15, 2025, 6:36 a.m.

When shopping for wireless earbuds, you’re immediately hit with a barrage of technical specifications. One of the most common is driver size, advertised in millimeters (mm). You’ll see 8mm, 10mm, and even 13mm, all marketed with the simple idea that “bigger is better.”

This is one of the most persistent and misleading myths in audio.

While driver size can influence sound, the material of the driver’s diaphragm—the tiny, paper-thin membrane that actually vibrates to create sound—has a far more profound impact on audio quality. A large driver made of a flimsy material will sound slow, muddy, and distorted. A smaller, well-engineered driver made of advanced materials will sound clear, fast, and powerful.

Understanding this difference is the key to finding a high-value product.

The Problem with “Bigger is Better”

A dynamic driver is essentially a miniature loudspeaker. Its diaphragm needs to perform a difficult balancing act: it must vibrate to create sound, but it must also be rigid enough to stop vibrating instantly when the signal stops.

When a large, cheap diaphragm (often made of a single, simple plastic) tries to reproduce deep bass notes, it can’t handle the power. It flexes and deforms, a phenomenon known as “driver breakup.” This distortion doesn’t just make the bass sound “boomy” and undefined; it also muddies the midrange and high-frequency sounds, making vocals unclear.

The Material Science of Sound: PEEK + PU

To solve this, engineers turned to material science. The goal is to find a material that is rigid (for clear highs), lightweight (for a fast response), and well-damped (to control bass). Since no single material is perfect, the best solution is often to combine them.

This brings us to the PEEK+PU composite diaphragm, a sophisticated piece of engineering that is increasingly finding its way into budget-friendly earbuds.

- PEEK (Polyetheretherketone): This is a high-performance thermoplastic. Think of it as the “treble” component. It is incredibly rigid and lightweight. Its stiffness allows it to vibrate for high-frequency sounds (like cymbals and vocals) with extreme precision, preventing the “tinny” or “smeared” sound common in cheap earbuds.

- PU (Polyurethane): This is a flexible, elastic polymer. Think of it as the “bass” component. It’s used for the outer edge of the diaphragm (the “surround”). Its elasticity allows for the deep, long movements needed to push air for low-frequency notes. Its high internal damping absorbs unwanted vibrations, resulting in bass that is “punchy” and “tight,” rather than a “boomy” mess.

By bonding these two materials, engineers create a single driver that gets the best of both worlds: the rigid PEEK handles the clarity, while the flexible PU delivers the controlled power.

The Real-World Case Study: Smart Engineering

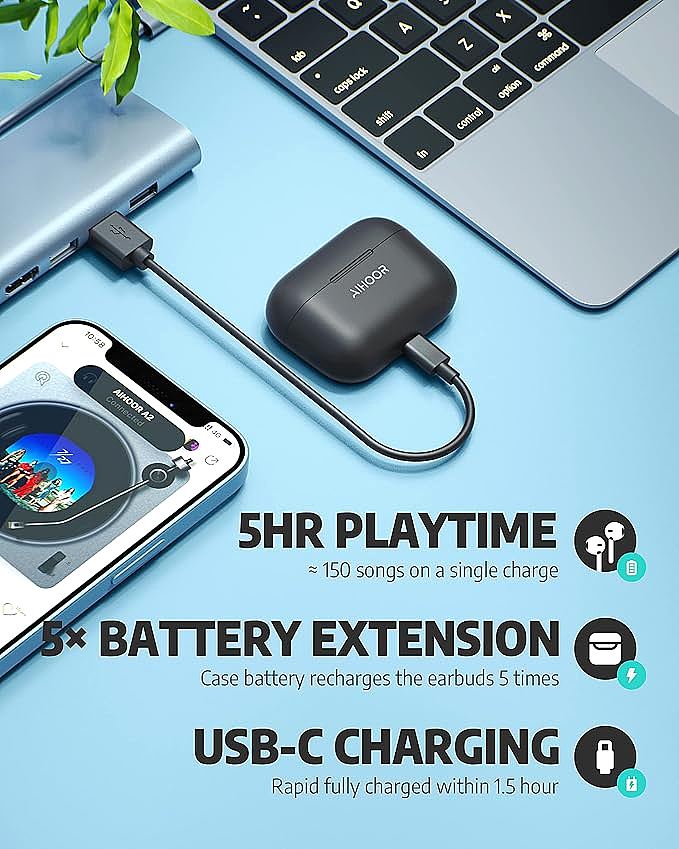

This PEEK+PU technology is no longer exclusive to high-end brands. It’s the entire design philosophy behind value-focused models like the AIHOOR A2. A quick look at user feedback for this model reveals two distinct camps: those who are “shocked” by the “fantastic, clean bass,” and those who claim the “bass is definitely lacking.”

This discrepancy is not a quality control issue; it’s a lesson in physics.

These advanced drivers are engineered for precision. To deliver that powerful bass (from the PU component), they require a perfect acoustic seal in your ear. This is known as Passive Noise Isolation (PNI). If the seal is broken, all the low-frequency sound waves leak out, and the audio sounds thin.

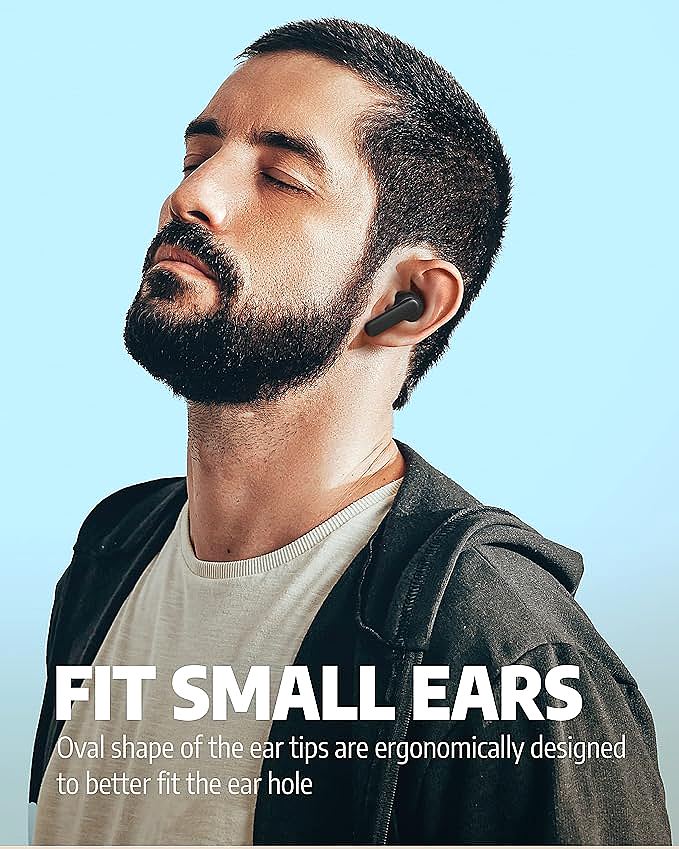

This is precisely why these earbuds are bundled with four different sizes of ear tips (XS, S, M, and L). They are not an optional accessory; they are essential to the product’s function. Achieving the correct seal is the only way to unlock the bass performance that the PEEK+PU driver is designed to produce.

The Art of the Compromise

This focus on driver material also explains the product’s “weaknesses.” To afford an advanced PEEK+PU driver in a sub-$30 product, compromises are non-negotiable.

- No ANC: The product page for the A2 explicitly states it does not have Active Noise Cancelling (ANC). This expensive electronic feature was skipped to allocate budget to the physical driver.

- Video Latency: Many users note a “noticeable delay” when watching videos or gaming. This is not a defect. It’s the result of using standard Bluetooth codecs (SBC/AAC) and omitting expensive, licensed low-latency codecs like aptX.

This is a classic example of “value engineering.” The designers made a conscious choice: they prioritized music sound quality (the driver) over features (ANC, low-latency gaming).

Conclusion: How to Be a Smarter Shopper

The next time you’re shopping for earbuds, don’t be fooled by the driver size race. A “13mm” driver made of cheap plastic will almost always sound worse than a well-made “10mm” driver.

Instead, look for the signals of smart engineering. A specification like a PEEK+PU composite driver is a powerful indicator that the design team focused on the physics of sound first. It proves that you don’t need to spend hundreds of dollars to get high-fidelity audio; you just need to know what materials to look for.