Commoditized Excellence: Deconstructing the Engineering Behind Budget Sport Audio

Update on Nov. 24, 2025, 6:52 a.m.

In the consumer electronics market, there exists a pervasive myth: price equals performance. While this linear relationship holds true for luxury materials or proprietary software, the democratization of manufacturing technology has created a new reality. Today, mature, high-performance components are available at a fraction of their historical cost.

The Boean U18 Wireless Headphones serve as a prime artifact of this industrial shift. Often dismissed as merely “budget-friendly,” devices in this class are actually triumphs of efficient engineering. They utilize established scientific principles—hydrodynamics, acoustics, and biomechanics—to solve specific problems for the active user. Let’s deconstruct the machine to understand the physics at play.

Acoustic Physics: The 11mm Displacement Advantage

At the heart of any headphone is the transducer, or driver. It is a simple piston, pushing air to create sound waves. The Boean U18 employs an 11mm dynamic driver. To the casual observer, this is just a number. To an audio engineer, it is a statement of intent regarding bass response.

Bass frequencies are long wavelengths that require significant energy to be audible. Producing them requires moving a large volume of air. The formula for the area of a circle ($A = \pi r^2$) dictates that even a small increase in diameter results in a significant increase in surface area. An 11mm driver has nearly 3.3 times the surface area of a standard 6mm driver found in many compact earbuds.

This increased surface area allows the diaphragm to displace more air with less excursion (movement), resulting in a visceral, physical bass response (“thump”) that is harder to achieve with smaller drivers without introducing distortion. For the athlete, this is not about audiophile neutrality; it’s about rhythmic entrainment. Strong low-frequency pulses effectively synchronize with running cadences, a psychoacoustic phenomenon proven to improve workout endurance.

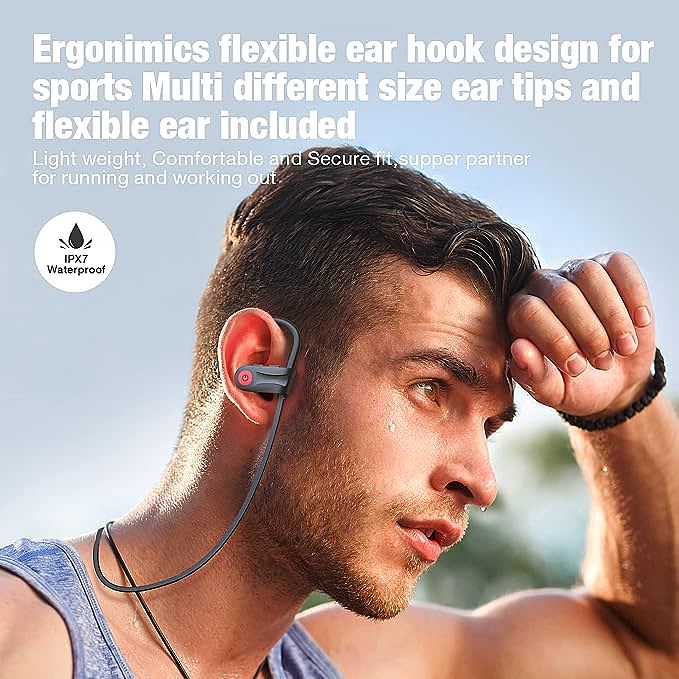

Biomechanics: Friction vs. Mechanical Interlock

Why do most earbuds fall out during a run? The answer lies in the limitations of friction. Standard “in-ear” buds rely on the static friction between the silicone tip and your ear canal. However, sweat acts as a lubricant, drastically reducing the coefficient of friction. As you run, vertical impact forces (g-forces) eventually overcome this weakened grip.

The U18 circumvents this failure mode through geometry. The flexible earhook design creates a mechanical interlock with the pinna (the outer ear).

By hooking over the ear, the device transfers the load from the delicate ear canal to the robust cartilage of the outer ear. Gravity and impact forces now work with the design, pulling the hook securely onto the ear rather than dislodging it. This is a biomechanical solution that no amount of advanced friction coating can match, making it the superior form factor for high-impact kinetics.

Material Science: The Reality of IPX7

“Sweat-proof” is a marketing term; IPX7 is an engineering standard. Defined by the IEC 60529 code, a rating of ‘7’ for liquid ingress protection means the device can withstand immersion in water up to 1 meter depth for 30 minutes.

Achieving this at a mass-market price point involves precise assembly techniques. It typically requires ultrasonic welding of the plastic chassis and the application of nano-hydrophobic coatings on internal circuitry. While the user may never swim with them, this rating provides a critical safety margin against hydrostatic pressure.

When you run, sweat doesn’t just sit on the device; movement can drive moisture into crevices with surprising force. Furthermore, sweat contains electrolytes (salts) that are highly conductive and corrosive. An IPX7 rating ensures that the internal seals are robust enough to prevent this corrosive saline solution from bridging connections on the PCB (Printed Circuit Board), which is the primary cause of premature failure in gym electronics.

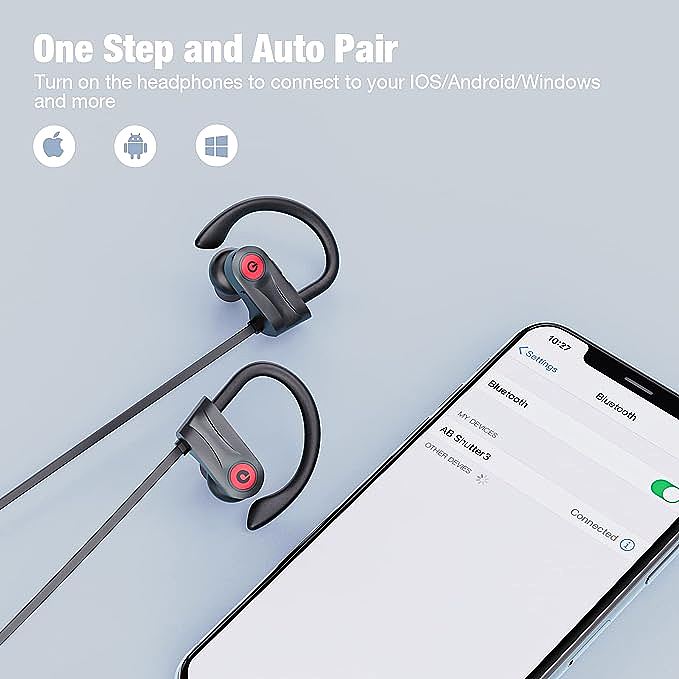

Connection & Energy: Bluetooth 5.3 Efficiency

The wire connecting the two earpieces of the U18 might seem “retro” in the age of True Wireless Stereo (TWS), but it offers distinct advantages in RF (Radio Frequency) stability and battery density.

In TWS earbuds, the signal must be transmitted to one bud and then relayed to the other (often through the user’s head, which absorbs 2.4GHz signals). The U18’s wired connection ensures perfect synchronization between left and right channels without radio interference.

Furthermore, the larger chassis afforded by the wired design allows for a larger Lithium-Polymer (LiPo) battery. Combined with the energy efficiency of the Bluetooth 5.3 protocol—which optimizes duty cycles to reduce power draw during idle states—this architecture enables the claimed 16-hour playtime. This is roughly 2-3 times the single-charge duration of typical TWS buds, solving the “battery anxiety” often faced by endurance athletes.

Conclusion: Value is an Engineering Metric

The Boean U18 demonstrates that high performance is not solely the domain of luxury pricing. By leveraging the physics of large drivers, the biomechanical security of earhooks, and the robust protection of IPX7 standards, it delivers a functional experience that rivals far more expensive competitors. It is a reminder that in the world of technology, smart engineering is the ultimate equalizer.