The Architecture of Value: Decoding the Engineering Behind Modern Budget Wireless Audio

Update on Nov. 22, 2025, 6:58 p.m.

The divide between “audiophile luxury” and “everyday utility” in the personal audio market is narrowing at an astonishing rate. Just a few years ago, features like extended battery life, waterproofing, and composite drivers were the exclusive domain of flagship products. Today, they are standard expectations even in the budget sector.

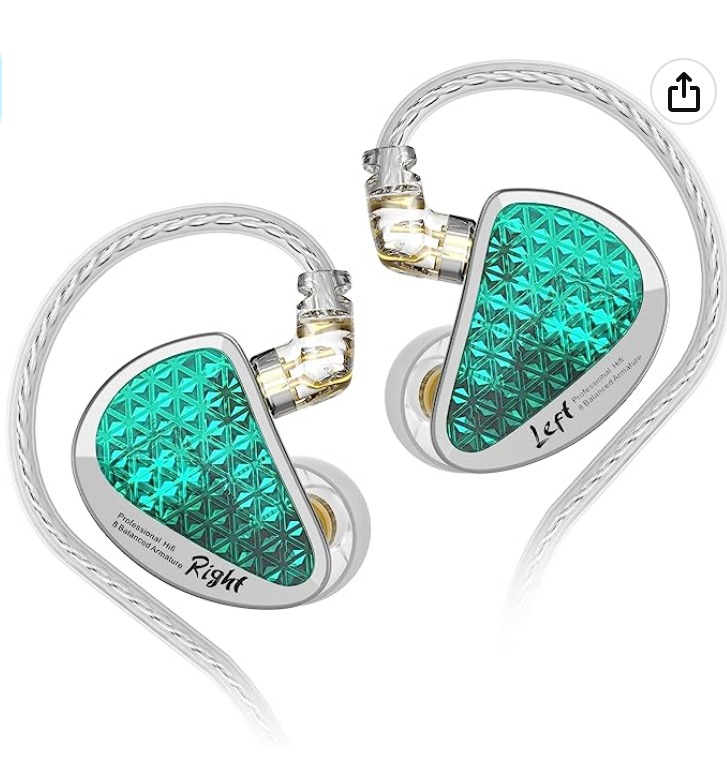

But how is this achieved? It isn’t magic; it’s value engineering. By prioritizing specific components and utilizing mature manufacturing processes, brands can deliver high-performance audio hardware at accessible price points. To understand this shift, we need to dissect the anatomy of a modern budget-friendly device. The DOBOPO Q13 Wireless Earbuds serve as an excellent specimen for this analysis, illustrating the deliberate design choices—and necessary trade-offs—that define this category.

The Physics of Fit: The “Semi-In-Ear” Acoustic Challenge

One of the most critical decisions in earbud design is the form factor: to seal or not to seal?

In-ear monitors (IEMs) use silicone tips to create a vacuum seal in the ear canal, physically blocking outside noise and trapping bass frequencies. Semi-in-ear designs, like the Q13, rest in the outer ear (concha) without sealing the canal. This design is favored for comfort, especially during long listening sessions or for users who find ear tips intrusive. However, it creates a significant acoustic challenge: Low-Frequency Leakage.

Without a seal, bass waves naturally escape before engaging the eardrum. To compensate for this, engineers cannot use standard-sized drivers.

The 13mm Solution

This is why you will often see larger driver diameters in semi-in-ear models. The DOBOPO Q13 employs a 13mm dynamic driver, which is considerably larger than the 6mm-10mm drivers found in many sealed earbuds.

- Air Displacement: A larger diaphragm moves more air. This increased displacement is necessary to generate enough bass energy to overcome the leakage inherent in the open fit.

- Titanium Stiffness: Moving a large diaphragm requires rigidity to prevent distortion (the “wobble” of the material). By coating the diaphragm in Titanium, engineers increase stiffness without adding significant weight. This allows the driver to maintain clarity in the highs (treble) while pushing the heavy air required for deep bass.

This engineering choice explains why users often describe the sound of such devices as “surprisingly punchy.” It is a calculated brute-force solution to the physics of an open fit.

Durability Metrics: Analyzing IP7 Waterproofing

In the consumer electronics world, durability is codified by the Ingress Protection (IP) rating. The Q13 boasts an IP7 rating (often denoted as IPX7), a specification that is frequently misunderstood.

The ‘7’ indicates protection against the effects of temporary immersion in water between 15cm and 1m for 30 minutes. For a budget device, achieving this requires precise assembly:

- Nano-coating: Internal components are often treated with a hydrophobic coating that repels water molecules.

- Sealed Architecture: Physical barriers prevent liquid entry at seams and ports.

Contextualizing Utility: While “waterproof” suggests you could swim with them, the reality of Bluetooth physics (radio waves do not travel well through water) and the hydraulic pressure of swimming strokes makes IP7 more relevant for accident protection and sweat resistance. For gym-goers, this rating is vital not because they plan to shower with their earbuds, but because sweat is corrosive. An IP7 rating ensures that salts and moisture won’t short-circuit the driver or battery over months of intense workouts.

The Energy Equation: Bluetooth 5.2 and Battery Density

How does a lightweight earbud (the Q13 weighs just 0.12 oz per bud) achieve 7-8 hours of playback? The answer lies in the synergy between battery density and chip efficiency.

Bluetooth 5.2 plays a pivotal role here. Compared to older iterations, 5.2 offers:

- Low Energy (LE) Audio: It optimizes the data transmission process, requiring less power to maintain a stable stream.

- Isochronous Channels: This feature allows data to be sent to both earbuds simultaneously (rather than daisy-chaining from one to the other), reducing the power load on the “primary” bud and balancing battery drain.

This efficiency allows manufacturers to use smaller, lighter Lithium-Polymer batteries without sacrificing longevity. The inclusion of an LED digital display on the charging case is another hallmark of modern value engineering—using low-cost, high-utility components to address the universal user anxiety of “how much charge do I have left?”

The Ergonomic Trade-off: Material vs. Stability

Engineering is the art of compromise. In the case of the Q13 and similar devices, the use of polished, high-gloss plastics serves two purposes: it looks premium and is easy to clean. However, this material choice interacts with the semi-in-ear geometry in specific ways.

Without the friction of a silicone tip, a smooth plastic shell relies entirely on the anatomy of the user’s antitragus and concha to stay in place. For many, this is comfortable and secure. For others, particularly those with smaller ears or during vigorous movement, the lack of friction can lead to instability—a phenomenon noted by some users as being “slippery.”

This is not a design flaw per se, but a characteristic of the form factor. It highlights the importance of understanding one’s own ear geometry when choosing between the friction-fit of silicone tips and the contour-fit of hard shells.

Conclusion: The Democratization of Audio

Devices like the DOBOPO Q13 illustrate a mature supply chain where advanced technologies—titanium drivers, IP7 waterproofing, and Bluetooth 5.2—are no longer gatekept by high prices. By understanding the engineering logic behind these features, consumers can look past the marketing fluff. The large driver isn’t just for “extra bass”; it’s a necessity of the open design. The waterproofing isn’t for scuba diving; it’s for longevity. In the end, value engineering doesn’t just lower costs; it makes robust, high-fidelity audio accessible to everyone.