The Anatomy of Endurance: Material Science in Personal Audio (Case Study: Jayfi JEB-101)

Update on Nov. 23, 2025, 9 p.m.

In the landscape of modern consumer electronics, there is an unspoken expiration date. We have grown accustomed to the “disposable” nature of our gadgets—cables that fray, plastic shells that crack, and batteries that inevitably die. This phenomenon, often termed “planned obsolescence,” generates massive amounts of e-waste and frustration.

However, against this backdrop of fragility, a counter-movement of engineering exists. It prioritizes tensile strength over trendiness and structural integrity over cost-cutting.

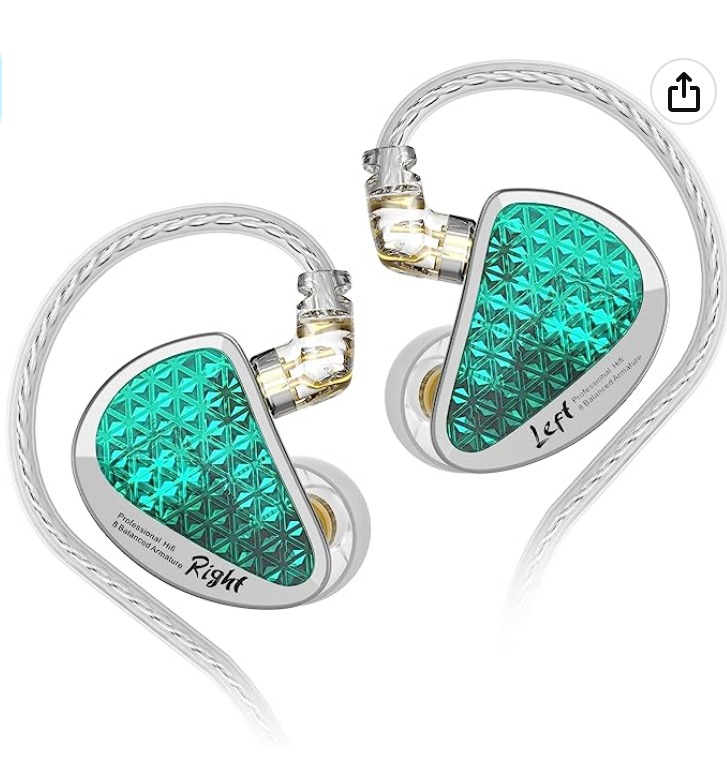

To understand what makes an electronic device truly durable, we need to look beyond the brand logo and analyze the materials used in its construction. By examining the Jayfi JEB-101—an in-ear monitor that users have reported using for years without failure—we can decode the specific engineering choices that contribute to longevity.

The Chassis: Metallurgy vs. Plastic

The vast majority of entry-level audio gear is encased in ABS plastic. While lightweight, plastic is prone to micro-fractures over time and is acoustically “lively”—meaning it vibrates along with the music, introducing unwanted coloration (distortion).

The first marker of a durable design is the shift from polymer to alloy. The JEB-101 utilizes a Hybrid Rare Metal Cavity. * Structural Integrity: Metal injection molding allows for a chassis that is virtually crush-proof in daily scenarios. The “UFO” saucer shape isn’t just an aesthetic quirk; structurally, domes and discs are excellent at distributing external pressure, protecting the delicate driver inside. * Acoustic Damping: From a physics perspective, mass is resistance to motion. A heavier metal shell resists vibrating when the driver pushes air. This means the sound waves are projected into your ear canal, rather than being wasted vibrating the shell casing. This results in what audiophiles call a “cleaner decay” of notes.

The Weakest Link: Cable Strain Dynamics

Ask anyone why they threw away their last pair of wired earphones, and the answer is almost always: “One side stopped working.” This is caused by internal wire fatigue, usually where the cable meets the plug or the earbud.

Engineering a solution requires borrowing technology from other industries. In the case of the JEB-101, the solution comes from the ballistics industry: Kevlar (Aramid Fiber).

- Tensile Strength: By weaving Kevlar fibers along with the copper conductive cores, the cable gains an internal “skeleton.” When you snag your headphones on a doorknob, the stress is absorbed by the Kevlar, not the fragile copper wire.

- TPE Shielding: Instead of standard PVC rubber, using Thermoplastic Elastomer (TPE) for the outer jacket offers high elasticity. It absorbs shock and resists the “memory effect” (where cables stay permanently kinked).

- Microphonics: TPE also has better internal damping, reducing the “stethoscope effect”—the thumping noise transferred up the cable when it rubs against your shirt.

The Engine: Composite Diaphragm Mechanics

Inside the metal shell lies the sound engine. Standard dynamic drivers use a single material (often PET plastic) for the entire diaphragm. The problem is a conflict of physics: logic dictates that bass needs a flexible material to move slowly and deeply, while treble needs a stiff material to vibrate quickly.

The engineering workaround is the Composite Double Diaphragm. By bonding different materials together, engineers can create a diaphragm that is stiff in the center (for clear highs) and flexible at the edges (for deep bass). This mechanical separation allows a single driver to cover a wider frequency range (20Hz–20kHz) with less distortion, mimicking the performance of more complex multi-driver systems without the added failure points of electronic crossovers.

The Variable of Seal: Viscoelasticity Explained

One of the most common complaints in audio reviews is inconsistent bass response—one user claims “earth-shattering bass” while another claims “tinny and weak.” Scientifically, both users are correct regarding their specific experience. The variable is the Acoustic Seal.

Bass frequencies are long waves that require a pressurized chamber to be perceived. If the ear tip doesn’t seal the ear canal perfectly, the bass energy leaks out effectively evaporating.

This is why the inclusion of Memory Foam tips is a critical engineering choice. Memory foam is viscoelastic—it behaves like both a viscous liquid and an elastic solid.

1. Compression: It compresses to fit into the ear.

2. Expansion: It slowly expands to fill every microscopic gap in the ear canal.

This creates a near-perfect vacuum seal, ensuring that the bass intended by the composite driver is actually delivered to the eardrum. It also provides passive noise isolation (up to -26dB in some tests), protecting hearing by allowing users to listen at lower volumes.

Conclusion: Investing in Physics

The Jayfi JEB-101 serves as a potent reminder that durability is not an accident; it is an engineering discipline. By analyzing the materials—Zinc alloys, Kevlar fibers, and composite diaphragms—consumers can look past marketing hype and identify products built to survive the real world.

When selecting your next piece of audio gear, perform a mental “material audit.” Look for strain relief, metal construction, and reinforcement. In a throwaway culture, choosing durability is the ultimate upgrade.