Wood Meets Silicon: The Acoustic Engineering of the Symphonized NRG C

Update on Nov. 23, 2025, 5:48 p.m.

In the digital age of audio, materials matter more than ever. While the market is flooded with injection-molded plastic and machined aluminum, the Symphonized NRG C opts for a material as old as music itself: Wood.

This choice is not merely aesthetic. It introduces specific acoustic variables—resonance, damping, and density—that fundamentally alter the sound signature. However, integrating organic materials with modern USB-C architecture presents unique engineering challenges, particularly regarding signal shielding. This analysis deconstructs the physics behind the wood housing and the invisible digital engine powering these earbuds.

The Acoustics of Organic Material: Damping vs. Reflection

Why make headphones out of wood? The answer lies in Internal Damping.

Standard plastic enclosures often suffer from “ringing”—unwanted resonances caused by sound waves bouncing off hard, uniform internal walls. Metal, while rigid, can introduce high-frequency sharpness. * Cellular Absorption: Wood is composed of cellulose and lignin in a complex cellular structure. This structure naturally absorbs excess vibrational energy. When the driver pushes sound waves backward into the housing, the wood dampens these reflections rather than bouncing them back into the driver diaphragm. * The “Warm” Sound: This physical damping is responsible for the “warm” tonal character often cited by users. It reduces the harshness in the upper-midrange frequencies (2kHz-4kHz), creating a smoother, more organic response that digital EQ struggles to replicate authentically.

The Invisible Engine: The USB-C DAC

Unlike traditional 3.5mm headphones which receive an analog signal, USB-C is a digital connection. This means the Symphonized NRG C is not just a pair of speakers; it is a complete audio system.

Hidden within the USB-C connector is a Digital-to-Analog Converter (DAC) and an amplifier chip. * Miniaturization: The engineering challenge is fitting a competent audio processor into a plug the size of a fingernail. This chip receives raw digital data from your phone and converts it into the electrical voltage that drives the speakers. * Signal Integrity: Because the conversion happens outside the noisy environment of the smartphone’s internal circuitry, USB-C earbuds can theoretically offer a cleaner noise floor. However, this depends entirely on the quality of the specific DAC chip used.

The Shielding Paradox: Wood vs. EMI

A fascinating, often overlooked consequence of using wood is its electromagnetic property. Wood is an electrical insulator, but it is transparent to electromagnetic fields.

Users report “static sound” or “feedback” when near radios or during idle times. This is a direct result of Lack of EMI Shielding. * The Faraday Cage Effect: Metal headphones act as a Faraday cage, blocking Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI) from reaching the driver wiring. Wood does not block these signals. * The Antenna Effect: In environments with high EMF (like near a radio transmitter or even strong Wi-Fi routers), the internal wiring can pick up interference that the wooden housing fails to reflect. This is the engineering trade-off: you gain superior acoustic damping at the cost of electromagnetic isolation.

Ergonomics: The Long Chamber Design

Reviewers note the earbuds are “weirdly long” and “stick far out.” This form factor is dictated by the acoustic requirements of the wood.

- Volumetric Tuning: To maximize the damping benefits of wood, there must be sufficient air volume behind the driver. A shallow wooden cap would act more like a hard surface. By extending the chamber length, engineers increase the internal volume, deepening the bass resonance

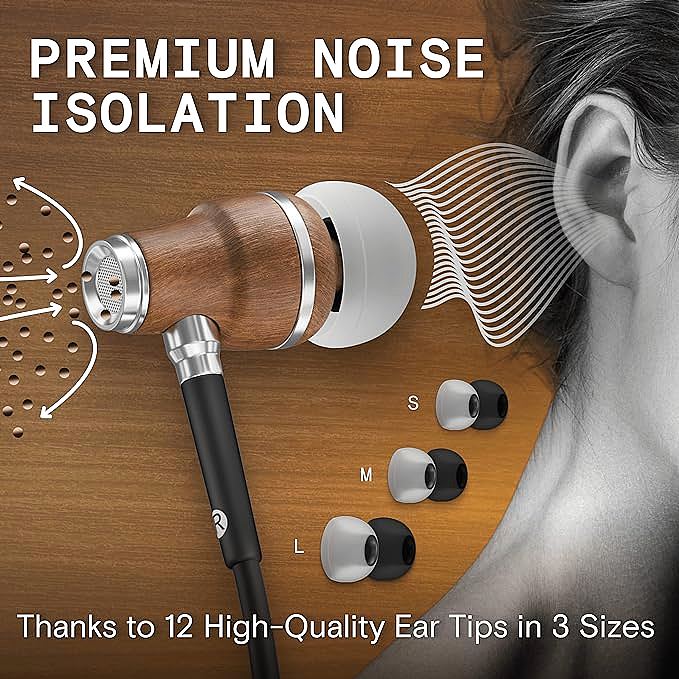

and enhancing the “wood effect.” - Leverage Effect: The downside is physics. A longer lever arm means the earbud is more prone to being dislodged by gravity or cable movement, necessitating a precise fit with the silicone tips to maintain the seal.

The Mixed-Material Bond: Manufacturing Tolerances

Reports of the “nubs” (nozzles) falling out highlight the difficulty of bonding disparate materials. * Thermal Expansion: Wood expands and contracts with humidity and temperature; the plastic or metal nozzle does not. Over time, this differential expansion can shear the adhesive bond holding the two parts together. This is a specific failure mode inherent to mixed-material consumer electronics that rely on glue rather than mechanical interlocking.

Conclusion: The Organic Trade-off

The Symphonized NRG C is a fascinating hybrid. It leverages the genuine acoustic benefits of wood damping to deliver a sound signature that stands out in a sea of plastic. However, it also exposes the raw physics of materials: wood cannot shield against interference like metal, and it requires more space to work acoustically. For the listener seeking a natural timbre and willing to accept these physical realities, it offers a unique, high-fidelity experience that defies its budget price point.